An asphalt mixing plant is a plant that are used for the production of asphalt concrete. In general, an asphalt batch plant can be used to produce bituminous mixture, modified bituminous mixture, colored bituminous mixture. It’s and eccential equipment used in the Construction of highways, grade highways, municipal roads, airports, ports.

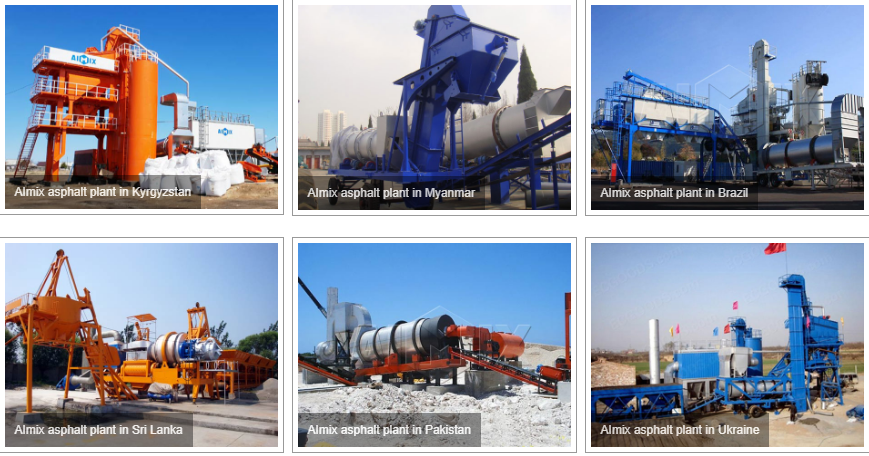

As a China construction machinery manufacturer and supplier, Aimix Group provides quality asphalt batch mix plants and sells them in reasonable price. In recent years, our asphlat mixing plants for sale have been exported to many overses countries such as Myanmar, Algeria, Brazil, Sri Lanka, Botswana, Pakistan, Ukraine, Tajikistan, Kyrgyzstan, Cook islands etc. The following is a picture that shows the distribution map of exporting countries in recent years.

Hot types of Aimix asphalt batch plants for sale

Aimix Group provides both stationary forced type asphalt plant for sale and mobile drum mix asphalt plant for sale. The following are hot types of Aimix stationary forced type asphalt plant for sale.

Advantages of Aimix stationary forced type asphalt batch mix plant for sale

- Compact modular design and integrated steel structure foundation, the layout is more reasonable, and the disassembly-transport-installation is faster and more convenient.

- Skirt-type feeding belt to ensure more stable and reliable feeding.

- Superior drying drum design and advanced self-developed combustion heating technology improve efficiency and reduce energy consumption.

- The plate chain type hot aggregate and powder lifting design improves the service life of the hoist.

- Plus high-rise hot aggregate silo design, increase the storage capacity of hot aggregate silos, eliminate the phenomenon of materials and increase production.

- Adopting the world’s advanced pulse bag dust removal technology, the smoke emission is less than 20mg/Nm3, which is in line with international high environmental protection standards.

- Fully automatic/manual control system with fault self-diagnosis feedback program, make it simple and stable to operate.

- Optimized design and high-energy conversion rate hardened gear reducer for high energy efficiency.

- The core components adopt internationally renowned brand products, such as Siemens motors and electrical components, EBICO burners, Swiss METTLER TOLEDO load cells, etc., which reduce the equipment failure rate and extend the service life of the equipment.

- The products have passed the CE certification of the European Union and the GOST certification of Russia. The products fully meet the requirements of quality, energy saving, environmental protection and safety in the European and American markets.

The following are hot types of Aimix mobile drum mix asphalt plant for sale

Advantages of Aimix mobile drum mix asphalt plant for sale

- Modular design, the main modules are equipped with trailer and chassis, which can realize rapid relocation and installation;

- High-precision screening, accurate metering, batch mixing, high quality of finished asphalt;

- Optimized design of drying drum and mixing tank, better equipment performance; key components are made of wear-resistant materials and have a longer service life;

- Simple design and small floor coverage.

- PLC system, intelligent control, easy to operate.

- Each module is equipped with a separate power distribution cabinet. The cables are arranged before leaving the factory, which is convenient and safe.

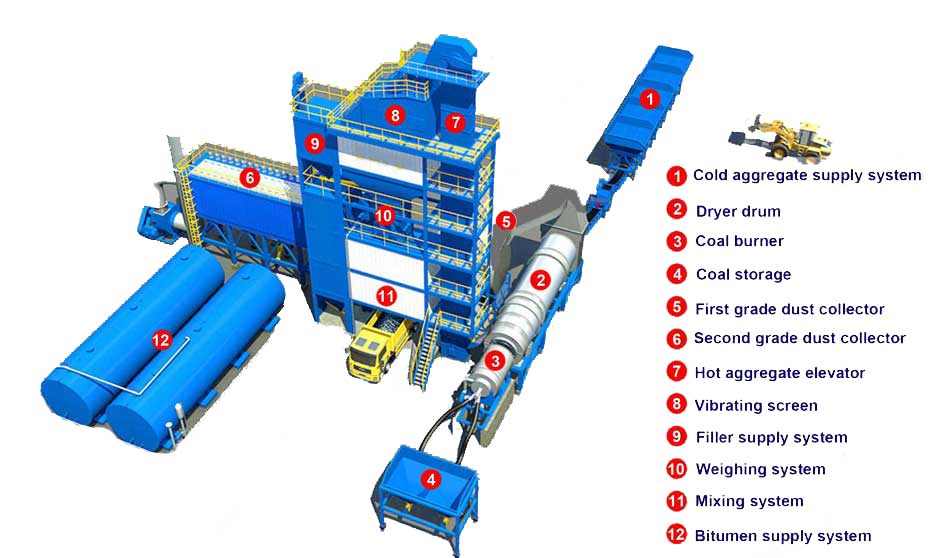

Components of a asphalt mix plant

Asphalt mixing equipment is mainly composed of batching system, drying system, combustion system, hot material lifting, vibrating screen, hot material storage bin, weighing mixing system, asphalt supply system, powder supply system, dust removal system, finished material bin and control system.

Simple introduction of asphalt batching plant working flow

The cold aggregates are stored in the cold aggregate batching machine, then the aggregates are transferred to the drying drum by the belt conveyor. Inside the drying drum, cold aggregates are dried. Once the aggregates leave the dryer, they are transferred to vibrating screen which does the task of separation of aggregates according to the size. After screened, the aggregates are dropped into separate hot storage bins.

About Aimix Group

History:

Aimix is a China construction machinery manufacturer and supplier that has more than 30 years’ experience of exporting construction equipment to oversea countries. With more than 30 years development, our company has become one of the leading professional manufacturers and exporters of Construction Machinery in China.

We have got certificate ISO9001:2000 and passed SGS test. At present, our products are popular at home and abroad.

Our Markets:

Our products have been delivered to more than 60 countries. Our asphalt mixng plants equipment have been exported to Tajikistan, Kyrgyzstan, Ukraine, Pakistan, Algeria, Sri Lanka, Brazil, Myanmar and other regions etc.

Our Services

Provide professional technical and project solutions;

Your inquiry will be replied within 24 hours.

Well-trained and experienced staff to answer all your inquiries in fluent English and Russia.

Factory visit is welcomed and free booking hotel and airport pick up service.

Engineers will go to clients’ site for guiding the installation and test-running;

Spare parts supply, when you need any spare parts, we will send to you as fast.

If you have any idea or demand, we can provide the customized products.

How About Aimix Asphalt Mixing Plant Price?

Aimix provides both standard models of bitumen plant equipment and customized models. Customers can give the information of their detailed requirement, our engineers will figure out the most appropriate plan for you. For example, the number of silo volume and hopper number adopted in the aggregate supply system can be customized according to user needs; the burner band can be chose etc.

In a word, our engineers will give you the most appropriate advice according to your actual demands. Customers just need to tell us the output they need, continuous type of forced type they prefer, raw material kinds, fuel type, the road construction grade, whether to add ore powder, whether they have special requirements in the country the equipment to be used. Aimix will give customers the most suitable asphalt batching plant with competitive price.

If you are interested in our asphalt mix plant equipment or have any questions, please leave a message in the form below or send email to us.