Aimix is a professional clay brick making machine manufacturer with many years’ industrial experience. We adopt advanced technology to ensure the machine have a good design and can work well. The high-quality clay brick making machines are sold very well at home and abroad.

Automatic clay brick making machine is also called red clay making machine. It adopts clay, coal ash, gangue, fly ash and broken stone as the raw materials. As one of the leading clay brick machine suppliers, we will supply high-performance clay brick machines at reasonable cost.

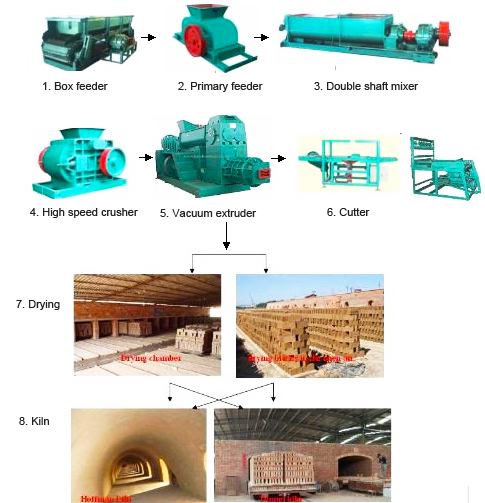

Working process of fully automatic clay brick making machine:

1. Through the box feeder, put the raw materials into the hammer crusher for preliminary crushing. Then the materials is transferred into the shaft mixing machine.

2. The extrusion machine will extrude the pug and then carry out parting according to the required dimension.

3. Unfired bricks are cut by cutter and the will be conveyed to the drying chamber work system.

4. After drying, bricks will be put in the kiln car for burning.

Features of clay brick machines:

1. Small power with high molding precision, energy saving equipment.

2. We adopt superior mixing shaft, ensuring the quality of clay brick.

3. The brick making machine has rational design, compact structure, smooth operation, can greatly reduce the consumption power by vibration in equipment operation process.

4. Good after-sale service and long working life.

Models and specifications:

| ABM-3S | Brick Size(L*W*H) | Pcs/Mould | Cycle molding | Pcs/Hr |

| 390*190*190 | 3 | 15-20s | 540-720 | |

| 200*100*60 | 10 | 15-25s | 1500-1800 | |

| 225*112.5*60 | 8 | 15-25s | 1200-1400 | |

| ABM-4SE | 390*190*190 | 4 | 24-26s | 580 |

| 240*115*90 | 9 | 22-25s | 1400 | |

| 240*115*53 | 21 | 22-25s | 3300 | |

| ABM-6S | 200*100*60 | 21 | 18-23s | 3287-4200 |

| 200*160*60 | 12 | 18-23s | 1878-2400 | |

| 240*115*53 | 32 | 15-17s | 6500-7800 | |

| 390*190*190 | 6 | 20-25s | 864-1080 | |

| ABM-8S | 200*100*60 | 28 | 18-23s | 4382-5600 |

| 200*160*60 | 20 | 18-23s | 3130-4000 | |

| 240*115*53 | 42 | 15-17s | 9000-10000 | |

| 390*190*190 | 8 | 20-25s | 1150-1440 | |

| ABM-10S | 200*100*60 | 31 | 18-23s | 4852-6200 |

| 200*160*60 | 21 | 18-23s | 3287-4200 | |

| 240*115*53 | 52 | 15-17s | 11011-12480 | |

| 390*190*190 | 10 | 20-25s | 1440-1800 | |

| ABM-12S | 200*100*60 | 38 | 18-23s | 5948-7600 |

| 200*160*60 | 25 | 18-23s | 3913-5000 | |

| 240*115*53 | 62 | 15-17s | 12700-14400 | |

| 390*190*190 | 12 | 20-25s | 1728-2160 |